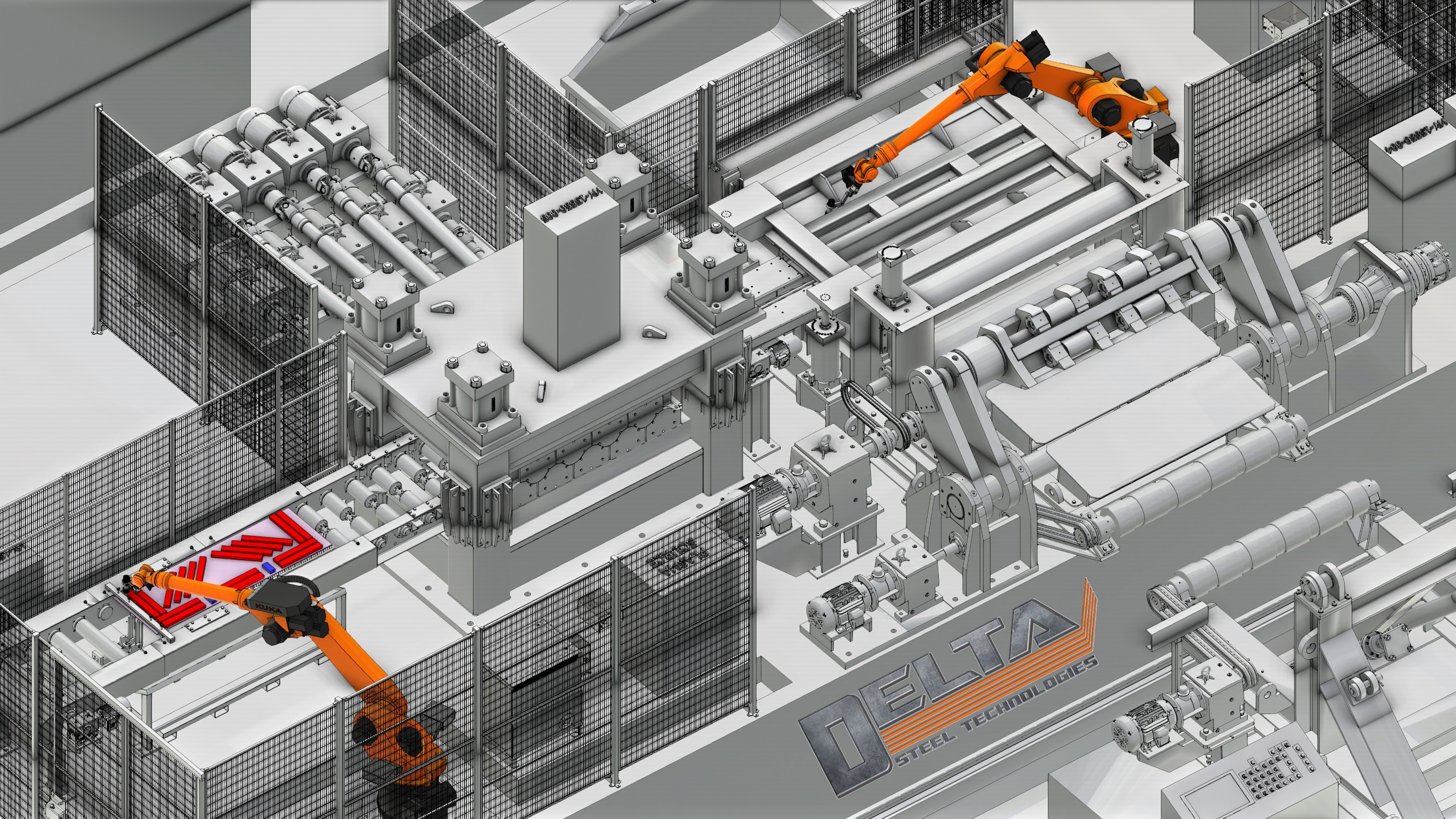

Delta Steel Technologies Showcases Next-Level Temper Pass CTL Line

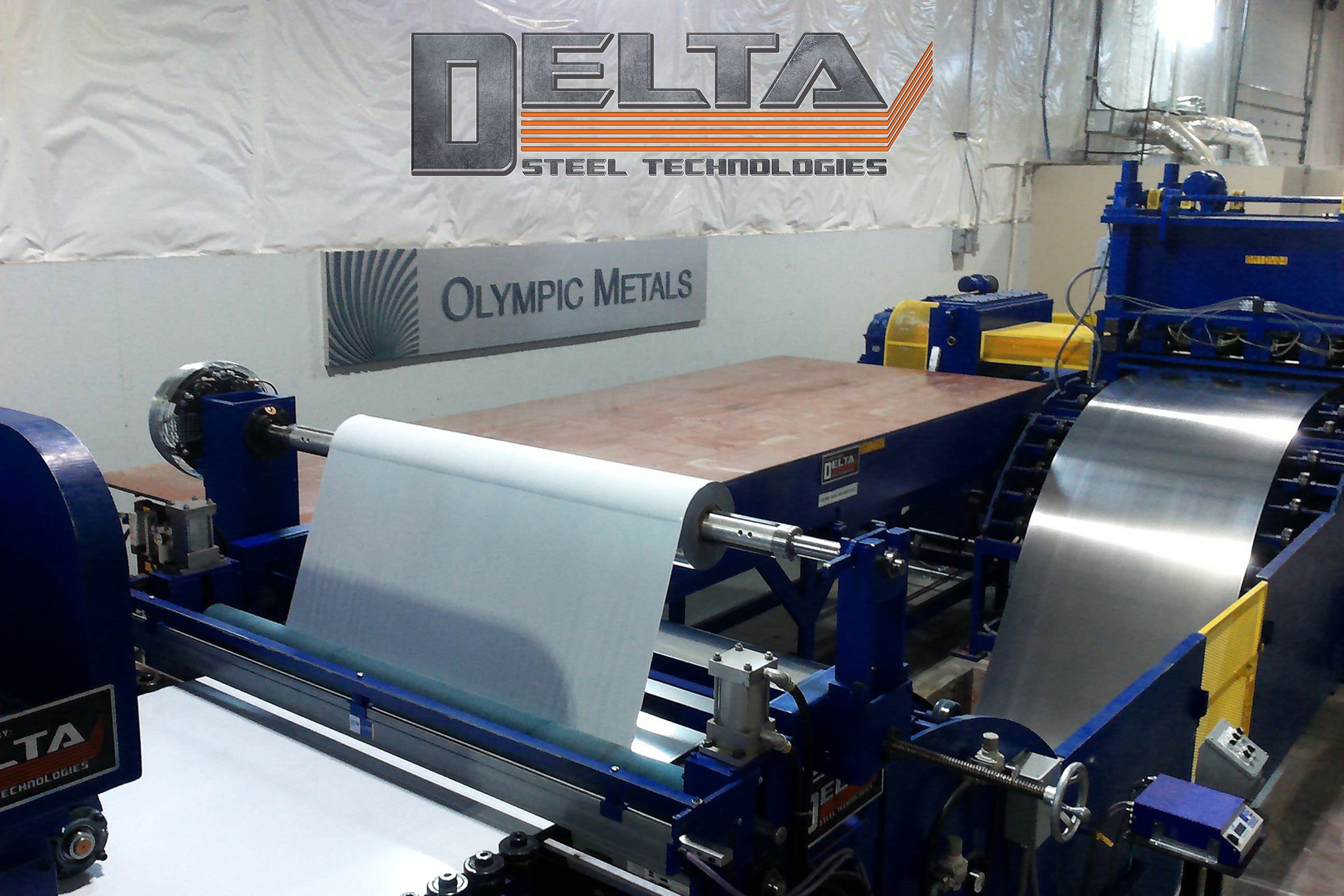

At Delta Steel Technologies, we pride ourselves on delivering more than just machinery — we deliver performance, precision, and innovation that drive the metals industry forward. In our latest video feature, we take you inside one of our most advanced Temper Pass Cut-To-Length (CTL) lines, ... Read More »